Understanding Injection Molding Machine Technology

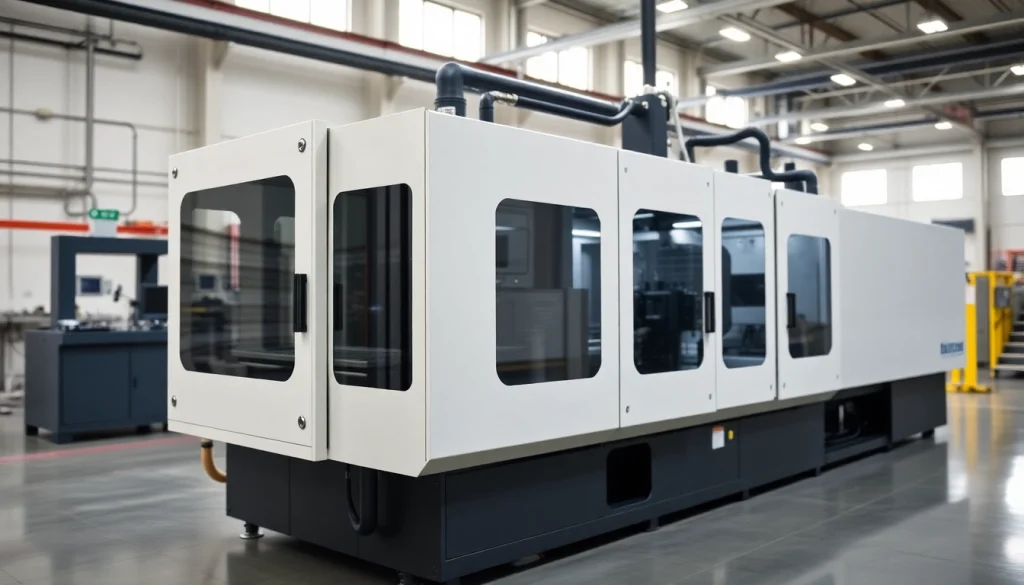

In the realm of industrial manufacturing, the significance of precision and efficiency cannot be overstated. Central to this conversation is the Injection Molding Machine, a critical piece of equipment that enables the mass production of plastic components with impressive accuracy and repeatability. The injection molding process is a cornerstone in various sectors, from automotive components to consumer electronics, establishing a crucial link between design and production.

Basics of Injection Molding Process

The injection molding process begins with the creation of a mold from a material such as steel or aluminum, which is designed to form specific shapes. The mold is heated and closed, after which plastic pellets are fed into an injection unit. The plastic is then melted, and under high pressure, it is injected into the mold cavity. Once the material cools and solidifies, the mold is opened, and the finished part is ejected. This process allows for high-volume production of intricate designs, making it ideal for manufacturing a wide array of products.

The Importance of Precision in Injection Molding Machines

Precision is paramount in injection molding. A slight variation in temperature, pressure, or timing can lead to defects in the final product. Advanced injection molding machines, such as the TEⅡ electric injection molding machine, utilize discrete intelligent drive control systems to ensure that positioning and pressure control are accurate. This degree of precision not only enhances the quality of the products being manufactured but also minimizes waste, thereby increasing efficiency and lowering costs.

Major Types of Injection Molding Machines

There are several types of injection molding machines available, each offering unique advantages based on specific manufacturing needs. The main categories include electric, hydraulic, and hybrid systems. Electric machines, like the Topstar TEII Series, are known for their energy efficiency and precision, while hydraulic machines, such as the Topstar TH Series, are favored for their power and versatility. Hybrid machines combine the strengths of both types, providing flexibility and performance.

Top Features of Electric Injection Molding Machines

Electric injection molding machines have gained popularity due to their innovative technologies and operational efficiencies. The Topstar TEII Series stands out for its high-rigidity templates and modular design, allowing for customization based on production requirements. It also features a user-friendly interface that enhances operability.

Advantages of All-Electric Models

All-electric injection molding machines offer numerous advantages over traditional hydraulic machines. They provide faster cycle times, are more energy-efficient, and require less maintenance. Furthermore, all-electric models minimize hydraulic fluid leakage, making them a more environmentally friendly option. The TEII series, for instance, showcases these advantages with its advanced drive systems that allow for precise movements and pressures.

Comparison with Hybrid Systems

Hybrid injection molding machines incorporate both hydraulic and electric technologies, combining their respective benefits. While all-electric models excel in energy efficiency and precision, hybrid systems can deliver more power and flexibility in certain applications. The Topstar TMII series exemplifies this by integrating servo-driven technology that allows for real-time feedback and control, accommodating complex product designs and ensuring higher production rates.

Energy Efficiency and Sustainability

As industries face increasing pressure to adopt sustainable practices, energy efficiency becomes more critical than ever. Electric molding machines are inherently more energy-efficient due to their lower power consumption during operations. By reducing energy expenditure, manufacturers not only cut costs but also lessen their environmental impact. The adoption of the TEII series, with its energy-saving technology, exemplifies a commitment to sustainability while maintaining high production standards.

Servo-Driven Injection Molding Machines Explained

Servo-driven injection molding machines represent a significant advancement in molding technology. The Topstar TMII Series showcases this innovation, providing precise control over the injection process, which enhances production quality and efficiency.

How Servo-Driven Machines Enhance Production

The unique design of servo-driven machines allows for the integration of various control systems, facilitating simultaneous operations and improving overall throughput. These machines provide enhanced control over movement and pressure, allowing manufacturers to produce complex parts with intricate designs. The real-time response feature means that any deviations in production parameters can be promptly adjusted, ensuring consistent quality.

Key Features of TMII Series

The TMII Series is designed with a focus on automation and precision. It includes features such as automatic compensation during mold openings, precise grasping capabilities with injection molding robots, and the ability to form densely packed plastic components seamlessly. This integration of technology simplifies operations and enhances productivity in high-demand manufacturing environments.

Achieving Complex Product Designs

One of the standout features of servo-driven machines is their ability to produce complex shapes and designs efficiently. The precise control offered by the TMII series allows manufacturers to incorporate metal inserts and achieve intricate details that would be challenging with other machine types. This flexibility not only opens up new design possibilities but also meets the varied demands of modern consumers.

Direct Press and Toggle Hydraulic Injection Molding Machines

Direct press and toggle hydraulic machines are essential for applications requiring significant power and stability in the injection molding process. These machines are well-suited for large-scale and heavy-duty production tasks.

Benefits of Direct Press Technology

Direct press technology offers numerous benefits, including higher clamping forces and greater precision. The Topstar TH Series, for example, features a two-plate center clamping structure that maximizes the mold opening stroke, making it particularly effective for deep-cavity products. This structure also accommodates the demands of automated part-picking applications, supporting operational efficiency.

Overview of TS Series Features

The TS Series Toggle Hydraulic Injection Molding Machine stands out due to its advanced oil circuit design and professional control systems. These features ensure stable machine movement, high product yield, and improved response times. By utilizing a dual injection cylinder system, the machine achieves precise and stable glue injection, further enhancing the quality of the molded products.

Applications and Use Cases

The range of applications for direct press and toggle hydraulic machines is vast. Industries including automotive, consumer goods, and packaging often rely on these machines to produce large and complex components. Their ability to handle high pressure and deliver consistent results makes them a preferred choice for manufacturers looking to maintain high production standards.

Choosing the Right Injection Molding Machine for Your Needs

Selecting the appropriate injection molding machine is critical for optimizing manufacturing efficiency and product quality. It involves evaluating various factors such as production volume, part complexity, and budget constraints.

Evaluating Production Requirements

Understanding the specific production requirements is the first step in choosing the right machine. Manufacturers need to consider the types of products they wish to produce, the volume of production, and the characteristics of the materials involved. This evaluation will help narrow down the choices between electric, servo-driven, and hydraulic machines.

Cost vs. Efficiency in Machine Selection

While cost is a significant factor in machine selection, it is equally important to consider the long-term efficiency and return on investment. All-electric and energy-efficient systems may have a higher initial cost, but their operational savings and reduced maintenance requirements can lead to lower overall expenses. Balancing upfront costs against long-term benefits is essential for making an informed decision.

Future-Proofing Your Manufacturing Setup

With the rapid evolution of technology and changing market demands, it is crucial to future-proof your manufacturing setup. This can be achieved by investing in flexible and adaptable machines that can accommodate new production techniques and materials. Choosing machines like the Topstar series, which offers modular designs and advanced features, will ensure that your manufacturing processes remain relevant and competitive in the face of ongoing advancements.